The Development Trend of PVC Artificial Leather

2022-11-29

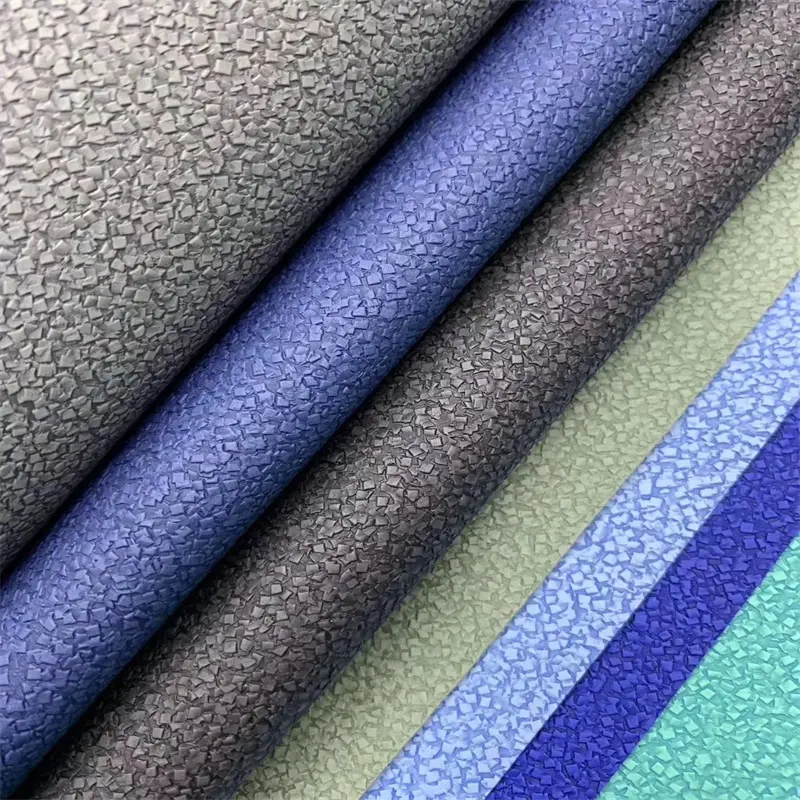

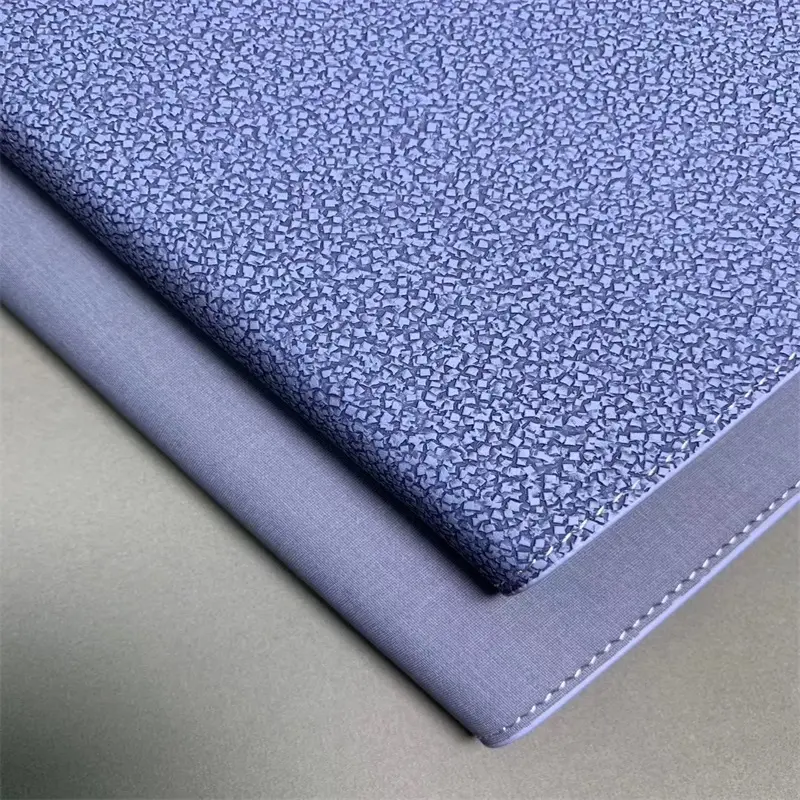

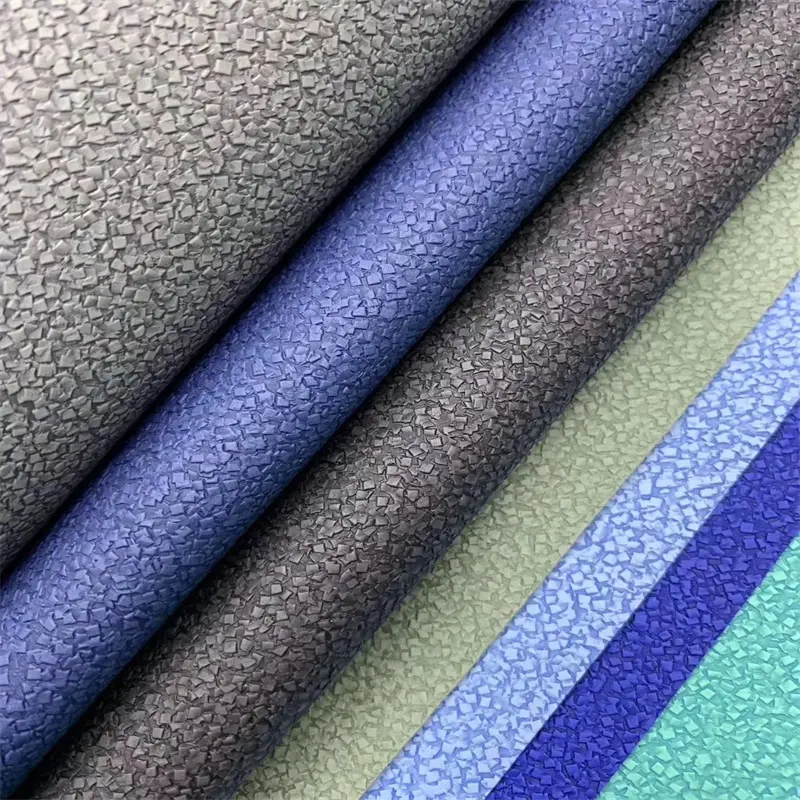

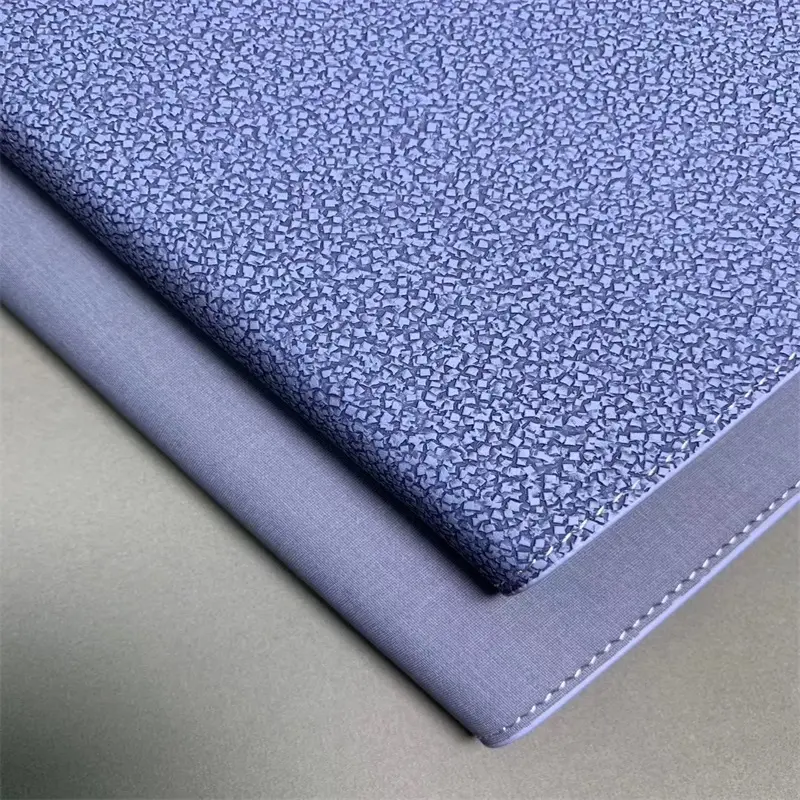

Pvc Artificial Leather is the abbreviation of polyvinyl chloride Artificial leather, also known as PVC Leather. It is a paste made of coating PVC resin, plasticizer, stabilizer and other additives on the fabric, or a layer of PVC film, and then through It is processed by a certain process. The product has high strength, low cost, good decorative effect, good waterproof performance, and high utilization rate, but most of the feel and elasticity still cannot achieve the effect of genuine leather; the longitudinal section has air bubble holes, cloth base or surface film and artificial fiber. It can be used for various bags, seat covers, linings, etc. It is mostly used in soft and hard bags in decoration.

Pvc Leather material properties and characteristics The traditional product of PVC artificial leather is polyvinyl chloride artificial leather, and later new varieties such as polyolefin leather and nylon leather appeared. PVC artificial leather is very similar to Natural Leather in terms of composition, structure, and appearance, and can almost replace it in any occasion where leather is used, and is used to make a variety of daily necessities and industrial products. (1) The grain of the leather surface is fine, the color is uniform, and there is no phenomenon of layering and cracking. (2) The leather body is plump, soft and elastic, with uniform thickness. (3) The leather is clean, non-greasy, and foams evenly. (4) It has certain strength, toughness, elasticity, wear resistance and cold resistance. (5) Good decorative effect, rich patterns and colors, environmental protection, flame retardant, light weight, easy processing, and low price. (6) Poor air permeability, hardening at low temperature leads to poor flexibility, cracks, poor slip resistance, and poor hand feeling. Product technology and classification In the manufacturing process of PVC artificial leather, the plastic particles should be hot-melted and stirred into a paste, and evenly coated on the T/C knitted fabric base according to the specified thickness, and then enter the foaming furnace for foaming to make it have a It is suitable for the production of various products with different softness requirements, and the surface treatment (dyeing, embossing, polishing, matting, and fluffing of the polished surface, etc., is mainly carried out according to the specific product requirements) when it is out of the oven.

PVC artificial leather can be divided into several categories according to the base material and structure, and is generally divided into the following types according to the production method: PVC artificial leather with scratching method, PVC artificial leather with direct scratching method, PVC artificial leather with indirect scratching method, also called transfer method PVC artificial leather (Including steel belt method and release paper method); calendering method PVC artificial leather; extrusion method PVC artificial leather; cylinder coating method PVC artificial leather. In terms of use, it can be divided into several types such as shoes, bags, and decorative materials. For the same kind of PVC artificial leather, according to different classification methods, it can belong to different categories, such as city cloth artificial leather, which can be made into ordinary scratch-coated leather or foam leather. Pvc Leather For Sofa, Pvc Leather For Car Seat is suitable for home decoration, bags, home leather, sofa leather, furniture leather, etc.